ZCleaner

Injector automatic cleaning system for round end liners.

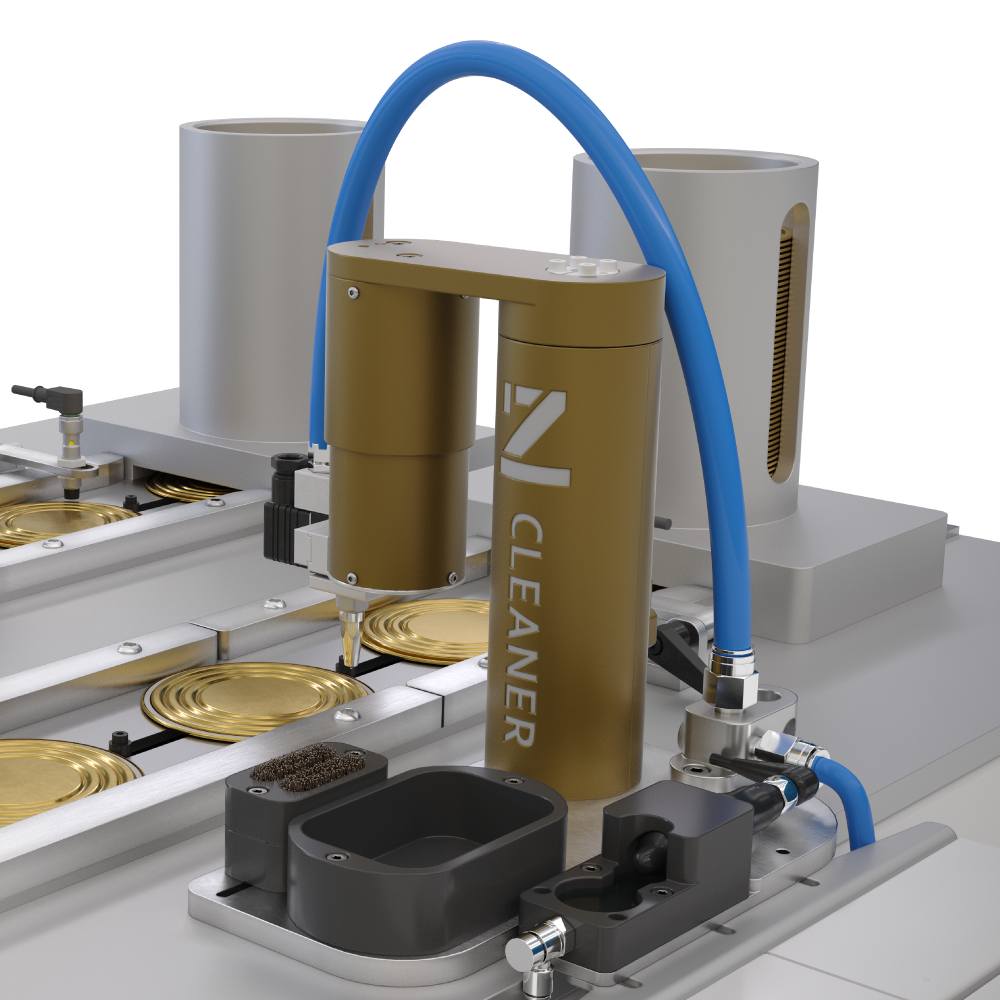

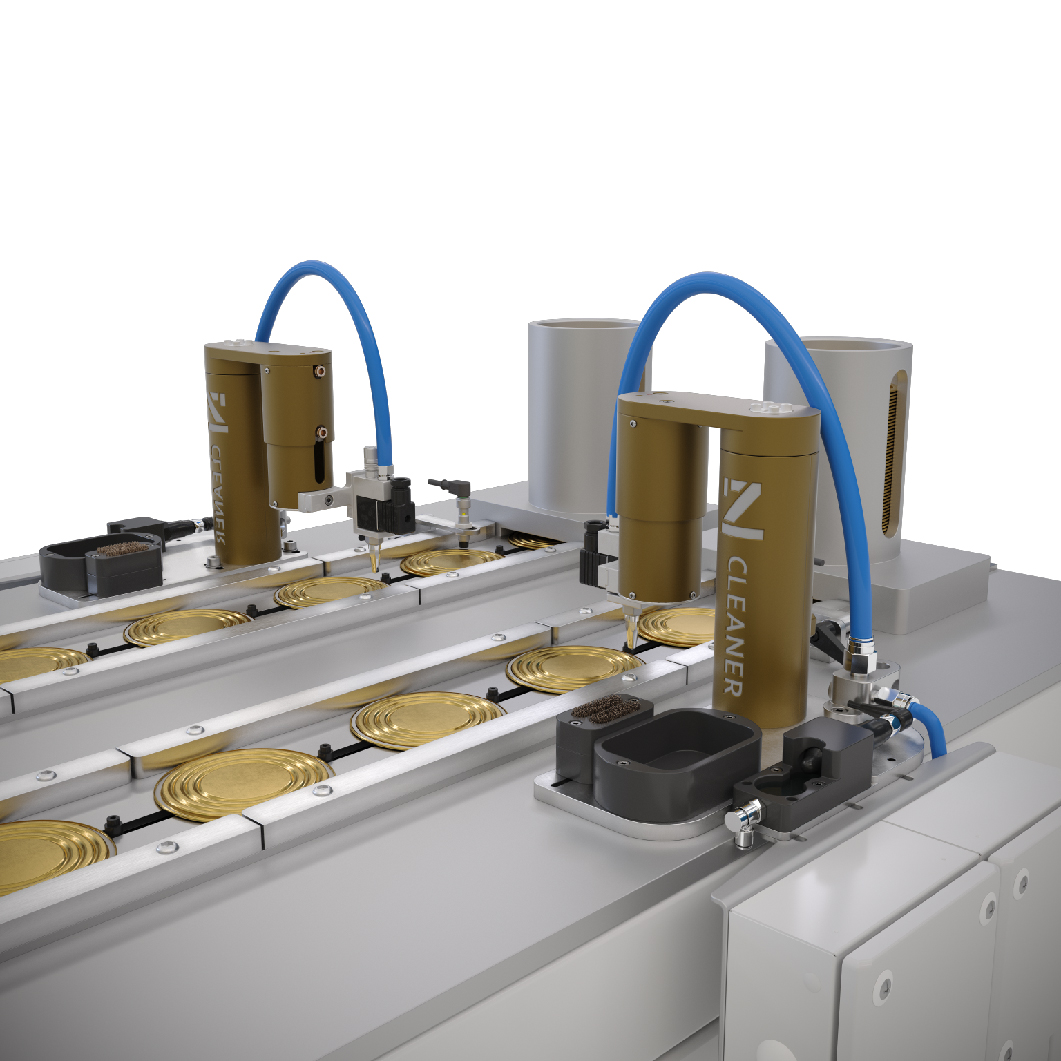

The ZCleaner cleaning system is based on one of the main concepts that incorporates the Spider Head Liner and is none other than the automatic cleaning station for the injector.

This accessory for round format liners is based on a small servo-controlled arm that allows the injector to move towards the cleaning area, which has a housing for purging, a cleaning brush and a housing for the airtight position of the injector. This airtightness is achieved by self-pumping a liquid (either water, food-grade vaseline or any other liquid) so that the injector remains submerged when the line stops.

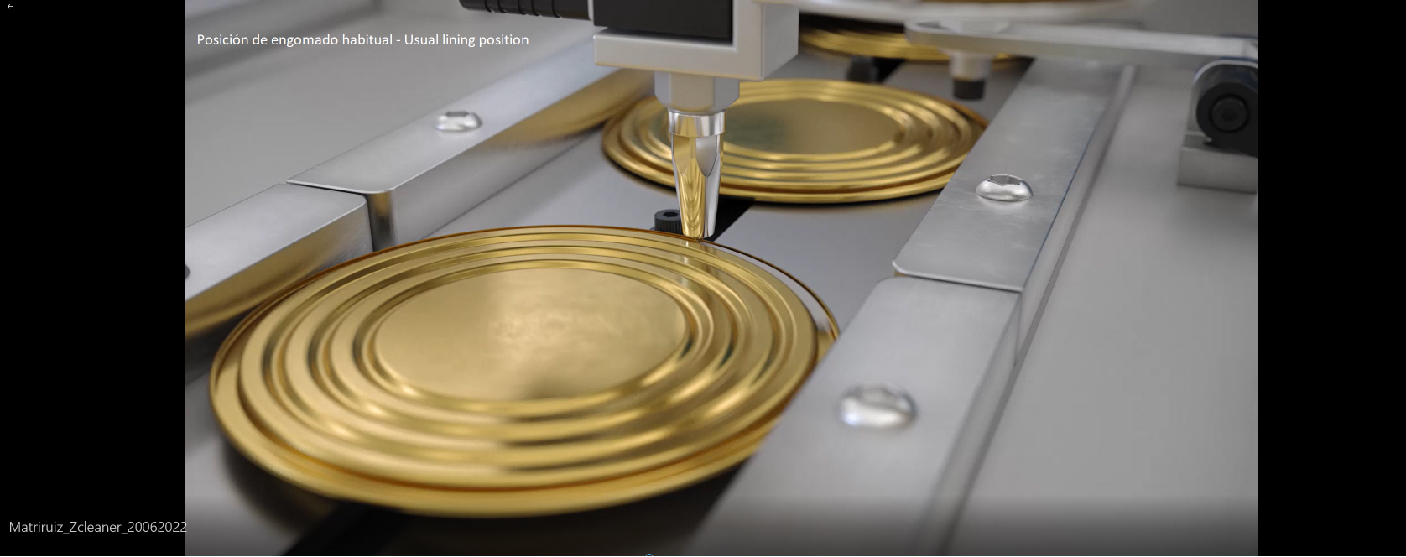

As in the head liner, the injector will go to cleaning every certain frequency (editable by the customer) or when the lining machine does not have ends. In the latter case, after cleaning, the injector will go to the airtight position until the liner has ends again.

This cleaning system is designed to be installed on any round format liner with transfer movement using the injector and the existing lining position.

Videos